- 1How to distinguish cable materials?

- 2How to conduct a visual inspection of wires and cables?

- 3How to evaluate the quality and performance of wires and cables?

- 4Troubleshooting of Low Voltage Automotive Wires: Common Problems and Solutions

- 5Application and Challenges of Low Voltage Automotive Wires in Electric Vehicles

- 6Analysis of Safety and Reliability of Low Voltage Automotive Wires

Analysis of Safety and Reliability of Low Voltage Automotive Wires

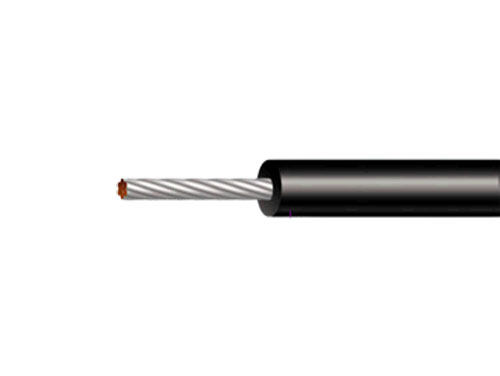

Low voltage automotive wiring harness is one of the key components inside automobiles, and its quality, safety, and reliability have a significant impact on the performance of automobiles. If the wiring harness fails, it will cause signal transmission failure and functional equipment to lose function; Or if the contact resistance is too high, it may cause heating and fire; Or short circuit fire; Or insulation layer failure and leakage.

In terms of vehicle wiring, most vehicle wiring is thin-walled low-voltage wiring or low-voltage wiring insulated with vinyl resin. Currently, an increasing number of vehicle functions and more complex electronic devices are using thin-walled low-voltage circuits. However, the thermal resistance and heat dissipation of thin-walled low-voltage lines used in vehicles are generally low. When frequently used, it is necessary to choose materials with strong heat resistance and heat dissipation. Generally speaking, cross-linked polyethylene heat-resistant low-voltage wires and cross-linked ethylene resin heat-resistant low-voltage wires are widely used in automotive applications.

The selection of fixing points is crucial in the design process of automotive wiring harnesses. The setting of good fixing points and the selection of fixing methods are the prerequisites for the reliability of wire harness layout. In addition, the reliability of wire harness design is a reflection of safety.

Overall, the reliability and safety of low-voltage automotive wiring harnesses depend on multiple factors, including the material, design, fixing method, and quality of terminals and connectors. Therefore, these factors need to be fully considered in the selection, design, and use process to ensure the safety and reliability of the wiring harness.

Combining strength and flexibility · Easy to move

Combining strength and flexibility · Easy to move

中文

中文