- 1How to distinguish cable materials?

- 2How to conduct a visual inspection of wires and cables?

- 3How to evaluate the quality and performance of wires and cables?

- 4Troubleshooting of Low Voltage Automotive Wires: Common Problems and Solutions

- 5Application and Challenges of Low Voltage Automotive Wires in Electric Vehicles

- 6Analysis of Safety and Reliability of Low Voltage Automotive Wires

How to conduct a visual inspection of wires and cables?

Conducting a visual inspection of wires and cables is an important step in ensuring their quality and safety.

Firstly, the appearance inspection mainly includes the following aspects:

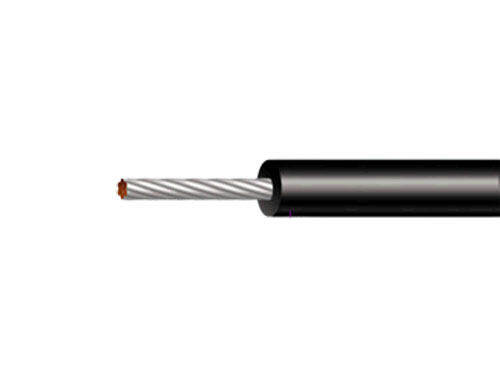

Check surface quality: Observe whether the surface of the wire and cable is round, smooth, and free of defects and impurities such as burrs, cracks, spots, oil stains, etc. These issues may affect the normal operation and insulation performance of the cable.

Confirm the integrity of the outer skin: Check whether the cable outer skin is intact, whether there are scratches, damages, peeling, and other conditions. Any damaged outer skin may affect the insulation performance and mechanical strength of the cable.

Verify identification information: Check whether the color of the cable sheath meets the standard requirements, and verify the identification information on the cable, including cable model, rated voltage, manufacturer, etc. The correct color and identification help identify the characteristics and purpose of the cable.

Observing surface defects: Carefully observe whether there are cracks, dents, bubbles, foreign objects, and other defects on the surface of wires and cables. These may be caused by defects in the production process, damage during transportation or installation, and other reasons.

Check for bending and folding: Check for abnormal bending or folding of the cable, which may cause damage to the conductors inside the wire and cable or pressure on the insulation layer.

Secondly, size inspection is also a part of visual inspection, including:

Measure outer diameter and thickness: It is necessary to sample and test the thickness of the insulation layer and the diameter of the wire. The sampling method should take a sample of one section of wire at least 1 meter apart and measure it with a micrometer.

Confirm size standards: The insulation layer thickness of various wires and cables should not be less than the relevant regulations, and the diameter error of various wire diameters should not be less than 1% of the nominal diameter.

In addition, structural inspection is a final inspection that combines visual inspection and dimensional inspection, ensuring that there are no defects in the appearance and that the dimensions are roughly accurate. This step can further ensure the quality of the wires and cables.

Overall, conducting a visual inspection of wires and cables is a systematic process that requires comprehensive consideration of multiple factors to ensure compliance with relevant quality and safety standards.

Combining strength and flexibility · Easy to move

Combining strength and flexibility · Easy to move

中文

中文