- 1How to distinguish cable materials?

- 2How to conduct a visual inspection of wires and cables?

- 3How to evaluate the quality and performance of wires and cables?

- 4Troubleshooting of Low Voltage Automotive Wires: Common Problems and Solutions

- 5Application and Challenges of Low Voltage Automotive Wires in Electric Vehicles

- 6Analysis of Safety and Reliability of Low Voltage Automotive Wires

How to evaluate the quality and performance of wires and cables?

Evaluating the quality and performance of wires and cables can be achieved through a series of testing indicators, and the following are some key evaluation methods:

Insulation resistance test: This is a basic test to measure the insulation performance of wires and cables, evaluating their quality by measuring the ability of insulation materials to block current.

Conductor resistance test: By measuring the resistance value of the conductor part of the wire and cable, it is possible to determine whether its conductivity meets the standard requirements.

Aging and stability tests: including thermal aging tests and thermal stability tests, these tests simulate the high temperature environment that wires and cables may encounter during long-term use, and examine whether they can maintain stable performance under stress.

Flame retardant characteristic testing: testing the combustion performance of wires and cables when encountering a fire source, ensuring that they can prevent the spread of fire and ensure safety in emergency situations such as fires.

Mechanical performance testing: including tensile strength, bending performance, etc., to evaluate the durability of cables under physical stress.

Electrical performance testing: such as dielectric strength testing, to evaluate the performance of cables when subjected to voltage.

Environmental adaptability testing: testing the performance changes of cables under different environmental conditions (such as humidity, temperature, corrosive environment).

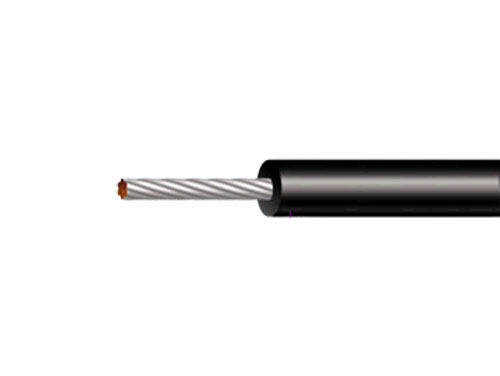

Appearance inspection: Check whether the outer skin of the cable is damaged, whether the markings are clear, etc. These are intuitive factors for judging the quality of the cable.

Size measurement: Ensure that the size of the cable meets the specifications, including wire diameter, length, etc.

Third party testing: Quality testing conducted by authoritative third-party testing institutions is usually more objective and comprehensive, and can provide more reliable evaluation results.

Manufacturer qualification review: Understanding the qualifications and reputation of the manufacturer, a manufacturer with a good quality management system can ensure the quality of wires and cables produced.

Related certifications: Check whether the product has relevant quality certifications, such as China Compulsory Certification (CCC).

Overall, through the comprehensive application of the above methods, the quality and performance of wires and cables can be comprehensively evaluated. At the same time, understanding the usage environment and conditions of the product and selecting wire and cable products suitable for specific purposes is also very important.

Combining strength and flexibility · Easy to move

Combining strength and flexibility · Easy to move

中文

中文